Table Of Content

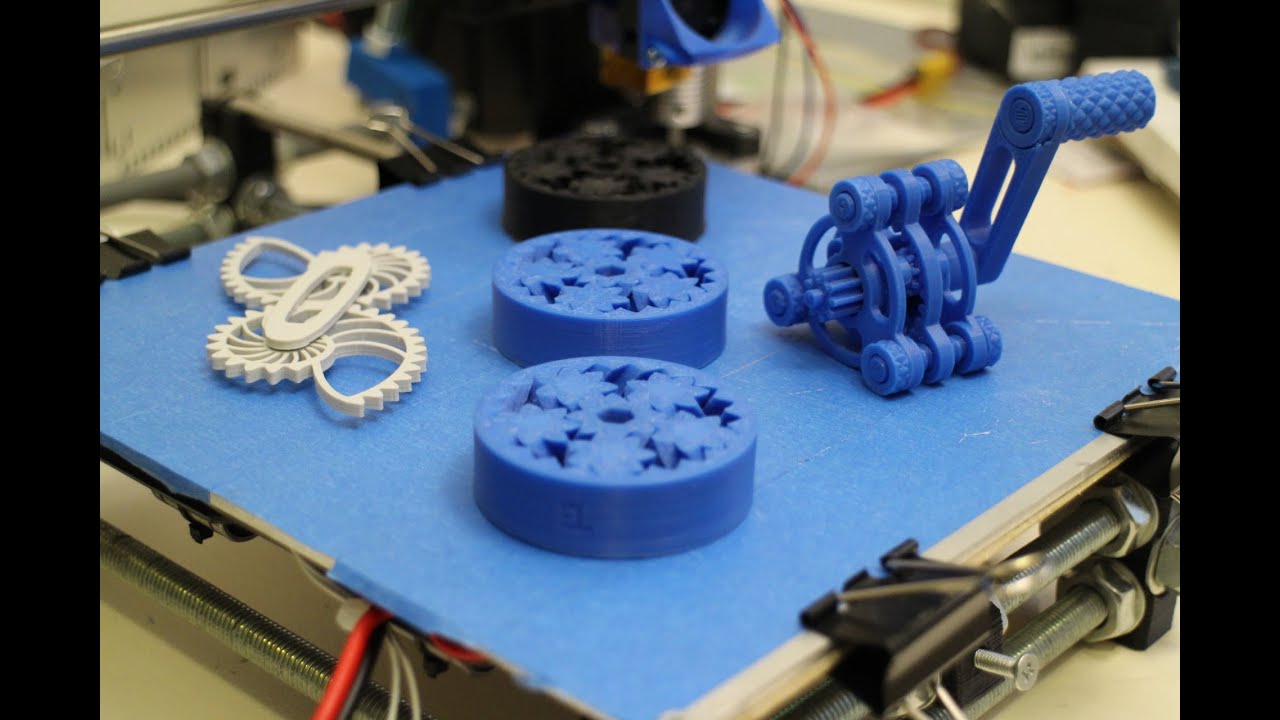

One of the many sophisticated 3D modeling software for 3D printing offered by Autodesk, Fusion 360 is an expert program that’s still usable by an educated beginner. Fusion 360 is used extensively in designing products for rapid prototyping prior to manufacturing runs, electronics designs, mechanical engineering, and more. UltiMaker Cura is free, easy-to-use 3D printing software trusted by millions of users.

TinkerCAD

The 30 Best 3D Printer Projects for Kids in 2024 - All3DP

The 30 Best 3D Printer Projects for Kids in 2024.

Posted: Fri, 19 Apr 2024 07:00:00 GMT [source]

Once completed, models can be exported to STL and OBJ file formats. 3DSlash is available in both a web browser version and a downloadable desktop version. Alongside, Tinkercad comes with a comprehensive library of tutorials, lessons, and learner projects perfect for those dabbling in modeling for the first time. In this guide, I’ll compare the best free CAD software for 3D printing across all the crucial details – from functionality and features to device compatibility and ease of use – so you can decide which is best for your project. An open source 3D printing tool for cleaning up 3D scans and enhancing models prior to 3D printing, MeshLab is a very sophisticated STL editing system.

Trials of Paid Software

Select all the objects in the bottom part of the box (i.e. everything but the lid). The machine revealed Tuesday at the University of Maine is four times larger than the first one — commissioned less than five years ago — and capable of printing ever mightier objects. That includes scaling up its 3D-printed home technology using bio-based materials to eventually demonstrate how printed neighborhoods can offer an avenue to affordable housing to address homelessness in the region.

DesignSpark Mechanical

Should you wish to print and build the box, you will need access to a 3D printer. This tutorial shows you how to use the Cura (LulzBot Edition) slicer program and print on a LulzBot. Also check which file types your slicing software is compatible with, so you can make your 3D designs into 3D prints.

Once you’ve entered your code, you can view the shapes you’ve created by clicking a “compile” button. This is a unique addition to the list of 3d printing software tools. Fusion 360 is a cloud-based 3D CAD program that utilizes the power of the cloud to bring design teams together and collaborate on complex projects. Another advantage of the cloud platform is that Fusion stores the entire history of the model including the changes to it.

Autodesk Fusion 360 [Design]

Skirts surround the part, but don't actually touch it, and they help warm up the extruder by establishing a smooth filament flow. By observing the skirt quality, you can adjust any leveling issues before printing your model. Printing with too high heat and not allowing the first layer to cool properly will increase the risk of a bulge, and make it hard to fit pieces together.

One of the biggest factors that will affect your 3D prints is the nozzle. The nozzle size and material will influence the strength, print time, and quality of your final product. While this is only true for FDM methods, similar resolution settings and issues will still appear with other 3D printing methods. 3D slicing software then translates the model into a set of G-code instructions interpretable by a 3D printer. Working hours on a model only to find out the program can’t export to a supported format is something you want to avoid. Consider what file types a particular CAD software for 3D printing supports, especially export formats.

Slicers & 3D Printer Hosts

While the blockish style can be limiting in terms of range of shapes one can make and less pleasing to the eyes, it is nonetheless efficient and practical. There are few software that are as quick from concept to finish as 3D slash. Holes are a special kind of 'overhang,' that 3D printers struggle to print. These shapes require the machine to create a round shape by layering materials on top of each other. Because the final layer at the top of your circle will be straight, the end result is a hole that's not quite round and doesn't quite match the diameter of the hole in your model. While valuable tools for beginners, programs like TinkerCAD can only help you create pretty rudimentary models due to their reasonably limited toolset.

Because FFF prints layer by layer, determining the print orientation early in the process helps drive design choices, text alignment, and snap features. Your 3D prints can only be as large as your printer’s build volume. Be sure to know its dimensions, then create a part that can either be printed within those dimensions in one go, or plan to use modularity (printing then combining separate parts). When designing for 3D printing, there are best practices to help you get the best results from your 3D printer and the parts it creates.

Repetier can also handle up to 16 extruders with different filament types and colors simultaneously, and you can visualize your end result before printing. There is a lot of customization and a lot of tinkering involved, making Repetier ideal for more advanced users. Despite its name, Ultimaker Cura can be used with almost any 3D printer because it is an open-source slicer. The program is ideal for beginners because it is intuitive and fast. More advanced users can access a further 200 settings to refine their prints. 3D Slash focuses on providing design software with a uniquely fun user interface and enough advanced features to work with a high level of precision.

Alternatively, you can design additional ‘dog point' heads onto your screw. This flat, unthreaded tip helps a successful print and is helpful for locating a groove on a shaft. You can print out the hole with the slightly flatter top, and use a screwdriver or similar tool to round it out after it's finished. Overhangs are fun to design and hard to print—here's where gravity puts up a fight. In order to print a geometry, it needs to have a volume, so a shape with “missing” surfaces or no volume isn't viable. This would be the equivalent of asking your 3D printer to print one straight line and expecting it to come out in 3D.

Then once you’re ready to print, the Monitor stage allows you to remotely observe progress, including displaying estimated time remaining and the estimated amount of filament required. Simplify3D is an extremely powerful premium slicing tool that helps you drastically improve the quality of 3D prints. Not only does Simplify3D slice your CAD into layers, it also corrects any problems with your models and allows you to preview the end result, helping to further identify any other issues. Advanced users will need to decide if the premium features are worth paying for compared to open-source slicers.

You may find that the thread you're trying to fit that screw into has nothing to do with the size of the thread on the screw anymore. The printer can then print a physical, real-world replica of the CAD software-created digital model. As a rule of thumb, opt for CAD software for 3D printing that includes STL exporting at the very least. It also exports to all your favorite 3D printing file formats like STL. It’s particularly forgiving to beginners, thanks to being a fun and very predictable way to dabble in 3D design for 3D printing for the first time.

Design parts optimized for 3D printing will improve print success rates, reduce costs through lower wastage, and boost the speed of your product development cycle. We design our software so anyone can use it – both experienced or rookie 3D printer users. However, if you change the shape of the bottom of the model so that it’s completely flat, and if possible also with a large surface area, then bed adhesion will be much better and your prints success rate will be much higher. Here are some tips I thought of that should improve your chances of success while printing the models you designed, since there are some fairly common mistakes you can make that may end up ruining your print. FreeCAD (Link to Review) is a general-purpose and open-source 3D parametric design software that has a wide range of uses.

No comments:

Post a Comment